PRODUCTS

For more than 25 YEARS Century Fab Tech manufactures a broad range of material handling equipments serving customers in various industries, including the construction, infrastructure, manufacturing, shipping, transportation, refining, energy, quarrying and mining industries.

Century Fab Tech provides customized material handling solutions for customer’s process specific requirements.

Double Girder EOT Crane

Capacity Ranging from 1,000 Kgs – 1,20,000 Kgs

Century Fab-Tech Double Girder EOT Cranes are available in higher capacities than the single girder, they give a better height of lift in a given headroom as the hook travels between the beams.

They can be used for heavy duty applications in industry such as:

- General Engineering Industries

- Steel & Foundry Industries

- Steel Stock Yards

- Granite Industries

- Wood Industries

- Railway workshops etc.,

The Double Girder design by Century Fab-Tech has one simple advantage of maintenance access to many critical parts of the crane as the design gives a possibility to fit in a walkway to the crane.

Single Girder EOT Crane

Capacity Ranging from 500 Kgs – 25,000 Kgs

Century Fab-Tech Single Girder Cranes are designed to provide an excellent value for money with no compromise on performance. These Cranes meet a wide range of modern industrial demands. These single Girder cranes has reduced wheel loads, saving costs on new support structures and increased lifting capacities on existing structures.

Gantry Cranes

Capacity Ranging from 1,000 Kgs – 1,00,000 Kgs

Century Fab-Tech Gantry Cranes come in whenever columns of the cranes track are obstacles or where because of long ways and considerable lifting, height, a high level crane track would over shoot costs. Century Fab-Tech continuously extends the operational range reaching both ends.

Interchangeable standard units with perfect details (electric hoists, crab, L.T drive units, driver’s cabin, safety devices etc.,) make Century Gantry Cranes the ideal choice for a variety of demanding application. Century’s Gantry Cranes are the “Cranes of Choice” for a wide range of open yard applications such as granite, ship building, storage yards, hydro power plants, mines , bulk material handling (with grab buckets), scrap yards and wood industries.

Jib Cranes

Jib Cranes by Century Fab-Tech. Jib Cranes comes in range from 500 Kgs to 5,000 Kgs.

Money saved is money earned. JIB Cranes are a money saver for every industry. Century Fab-Tech has the solutions for any localized material handling task with specific JIB Cranes and lifting tackle with a wide range of types and capacities. Nothing imposes Century Fab-Tech’s JIB Cranes for localized handling of any load, economically & efficiently in a minimum floor space.

STANDARD RANGE:

- Free standing self support

- Low head room self supported 360 degrees

- Self supported 180 degrees

- Self supported 360 degrees

BRACKET TYPE AND OTHER VERSIONS

- Wall bracket type

- King post type

- Moving Cantilever Crane

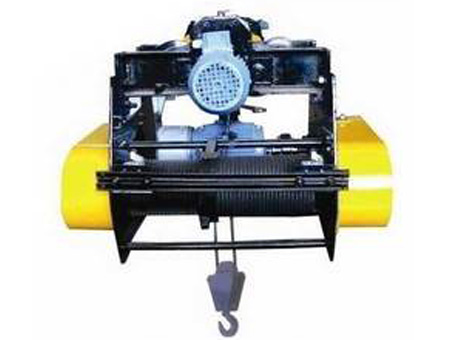

Electric Wire Rope Hoists

Capacity Ranging from 500 Kgs - 25,000 Kgs

Century Fab-Tech Electric Wire Rope Hoist are used by all core industries and are known for their enduring quality and complete reliability under most exacting conditions. Century Fab-Tech hoist are optimally designed and manufactured under stringent quality control as per the latest IS/BS Standard up to 25 Ton Capacity. Century Fab-Tech hoist are most compact, effective and designed in such a way that exceeds customer expectation.

Wire Rope Winches

Capacity Ranging from 1,000 Kgs – 2,00,000 Kgs

Century Fab Tech offers a diverse range of electric and hand wire rope winches for lifting, lowering, pulling and positioning loads to meet your specific needs. Electric wire rope winches provide superior performance when lifting speeds / pulling speeds are vital.

Hand Operated Crane ( H O T CRANE)

Hand chain driven manual bridges are operated by pulling a chain that is looped over a chain wheel to turn the drive shaft and the drive gears on the bridges wheels. Due to the relatively slow nature of a manual chain hoist, they are recommended for use in applications that require precision spotting.

As the loads increase in size and weight, hand chain bridge cranes are preferred over manual push/pull cranes. The heavier the load, the more force it takes to move it. Another advantage of the hand geared overhead traveling crane is that it can be operated at a safe distance from the load.

- Can manipulate loads up to 15 ton in capacity.

- Higher capacities are available with the use of a double girder crane.

- Spans of these types of overhead traveling cranes are generally limited to 50 ft.

- Use for maintenance, die handling, and fabrication assembly application

Freight Lift / Dumb Waiter

Capacity Ranging from 500 Kgs to 5000 Kgs

CENTURY FAB TECH specializes in design and manufacture of Dumb waiters for all multi-level establishments in India.

The lifts manufactured by us for every customer are as per specific individual requirements. In other words we customize as per your specific needs, pertaining to the type of materials (Garments, Pharmaceuticals, Hospitals, Chemical industries, Food Industries, Automobiles, Raw material handling, Tool rooms etc) size and weight to be handled.

We offer wide range of combinations to choose from i.e. different types of cabin, doors, openings, structures cladding and other features make CENTURY Dumb waiter very versatile to suit all types of environments.

OTHER PRODUCTS

* Electric Transfer trolleys capacity ranging from 1,000 Kg to 1,80,000 Kgs

* Container loader for granite industries to load the granite slabs to the closed container.

* 'C' Hooks for handling Steel Coils.

* Lifting Beams for handling lengthy Materials.

providing personalized and high quality services.

Request QuoteSALIENT FEATURES OF CENTURY FAB-TECH CRANES:

CRANE BRIDGE:

The girders of the crane are of Box-type construction which has the following definite advantages:

- RELIABILITY

It is our shop practice to X-ray all the main butt weld joints of the web and flange plates of the girders. Thus 100% reliability of the welded joints is ensured.

- VIBRATIONS

The load when released from the hook of the crane causes invisible vibration in the girders. These vibrations if not arrested within a short time, are easily transmitted to mechanical and electrical components and also to the gantry girders rail. This phenomenon causes detrimental effects on the performance of the crane.

We incorporated special design to damp the vibrations in less than 15 seconds in the general purpose cranes. This design feature is vital for the smooth performance of the crane.

- MORE TORSIONAL REGIDITY

Heavy torsional moments due to starting, stopping and plugging of long travel mechanism and also eccentrically placed masses like long travel machinery etc., Calls for torsional rigid girders. Box girders have much more torsional rigidity than any other type of girder construction.

MOTORS:

For all the motions, totally enclosed slip ring / squirrel cage type half hour rated motors will be provided. The motors are impregnated with ‘F’ Class insulation, suitable for tropical climate, high humidity and designed as per latest ISS.

BRAKES:

The hoisting, cross travel and long travel motors are directly coupled to the respective gear boxes and on the coupling an Electro Hydraulic Thrustor operated brake is provided. The brake applies automatically when current supply is OFF.

GEAR BOXES:

The maximum transmission efficiency is achieved by providing totally enclosed, split type, machine cut heat treated gears and pinions running in oil bath. CENTURY FAB-TECH provides HR & VR series gear boxes which are specially designed for each motion and service duty. All gear boxes standardised to achieve inter-changeability of gears for the different gear boxes.

BEARINGS:

All the moving parts of the crane are supported on anti frictional ball or roller bearings and no recourse is made to the use of bush bearings. The cross travel and long travel wheels are fitted with specially designed spherical roller bearings which can withstand axial trust in addition to radial thrust load.

WHEEL ASSEMBLY:

Special type bearing support blocks of ‘L’ type design (commonly known as ‘L’ type bearing) are provided on either side of CT & LT wheels. This arrangement can be incorporated only when complete speed reduction is through totally enclosed oil bath reduction gear boxes, which has already mentioned, are incorporated in our Cranes.

ROPE DRUM:

The hoist rope drum is of fabricated mild steel duly stress relieved, having Right and Left hand spiral grooves machined to suit the hoist rope. The drum will be of such size that there will not be more than one layer of rope on the drum when the rope is fully wound.

OPERATION:

The Crane will be operated from the floor by suspended push button pendent. Close or open type cabin can be provided with master controllers for all motions at extra cost.

LIMIT SWITCHES:

The hoisting motion of the crane is fitted with two-way rotary type limit switch to prevent over hoisting as well as over lowering.

The Cross travel and long travel motions of the crane are fitted with two way lever type limit witches to limit the movements within pre-determined ranges.

GEAR COUPLINGS:

The entire transmission system on the output shaft of the cross travel and long travel gear boxes is designed with use of geared flexible couplings which have the following advantages:

- Simple in design and composed of few parts.

- No rubber bushes to require frequent replacement.

- It is self aligning with no binding action at any point.

- Simple to align, install and easy to maintain.

- Accurately engineered for ultimate performance.

- Exceptionally long life.